Usage:

FM-1050E fully Automatic High Speed Vertical High-precision and multi-duty laminator as a professional equipment used for plastic film laminating on the surface of paper printed matter. Widely applicable for laminating in packaging, paper box, books, magazines, calendars, and commercial cards fields, Improving the printing matter grades, and achieve the purpose of dustproof, waterproof, oil proof. it’s the best choice for printing and laminating enterprises of all scales.

Machine brief:

FM-1050E fully Automatic high speed Vertical High-precision and multi-duty laminator is a newly developed product geared to the market demand, which is specially designed for water-based and dry laminating glue. The main unit is applied in cementing, drying and laminating, easy to operate. It can be used for multiple purpose, such as oil-type, water-based, and dry-type lamination. It is a new style film laminating machine. The chain knife cutting device (optional) specially for cutting thin paper which laminated for PTE, PVC film, also, it is suitable for cutting various thin films.

Technical parameters:

Model | FM-1050E | FM-1050E (Clear powder) |

Max. paper size | 1050×1050mm | 1050×1050mm |

Min. paper size | 390×320mm | 390×320mm |

Paper weight | 100-500g/㎡ | 100-500g/㎡ |

Overlap precision | ≤±2mm | ≤±2mm |

Working speed | 10-80m/min depend on paper | 10-80m/min |

Machine size | 84000*2200*2600mm | 102000*2200*2600mm |

Machine weight | 8000kg | 8500kg |

Machine start working only 3 minutes. | ||

Remark: accept customization of equipment in various specifications

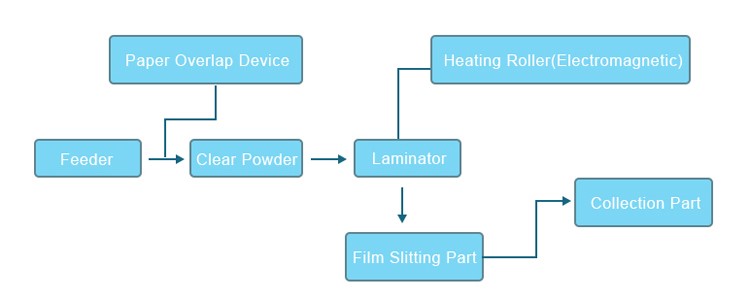

Processing line:

paper feeding unit, Edge landing unit, powder removing unit(optional), hot-press roller (electromagnetic heating), laminating mainframe, paper cutter, paper collecting machine

Machine image:

Pls refer to the link of the video. https://youtu.be/mmihOx1LagA

Machine function brief:

This feeder head also for high-speed printer with stable paper feed and keep accurate.

Paper feeding and collecting function without shutdown, effectively shorten the time of working.

Edge landing unit with servo control guarantees accurate and reliable edge landing.

Adopt coating by the chrome treatment roller, save the glue quantity and have evenly coating.

Strong hot air circulation could rapid drying

Anti-crimping device is suitable for thin-paper coating.

The heating steel roller adopts the electromagnetic heating system with rapid heating, energy saving and environmental protection.

Human-computer interface with touch screen, convenient and individualized

Industrial design, beautiful and elegant appearance, develop its own features

Mechanical color according to the actual picture video is for reference only, technical parameters performance and characteristics are subject to change without prior notice!