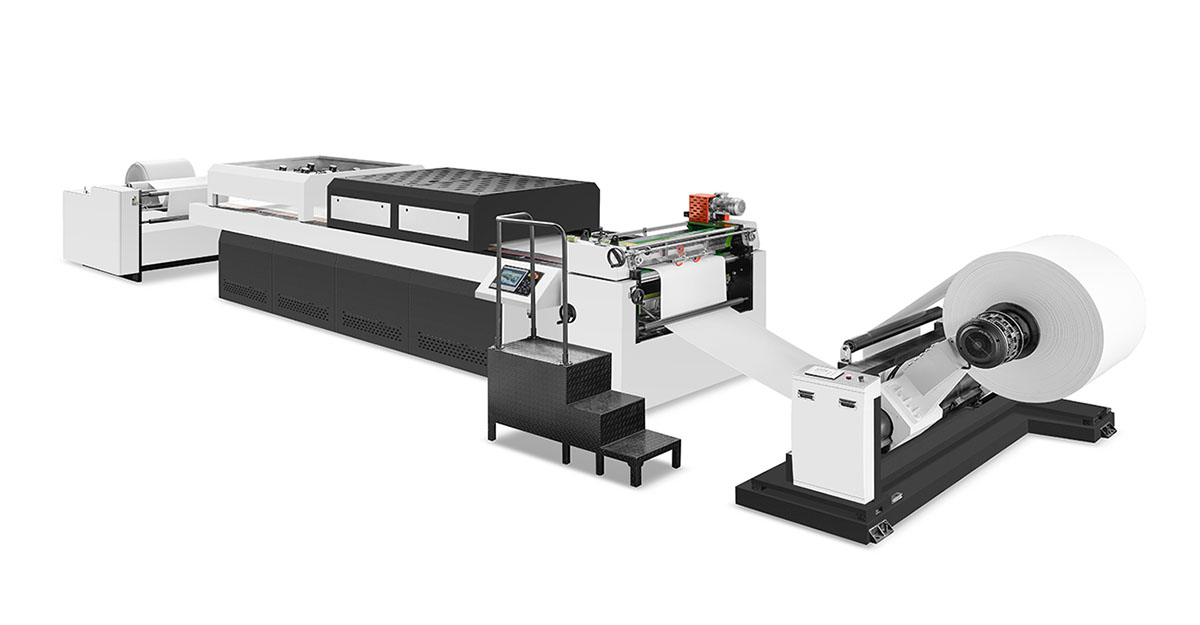

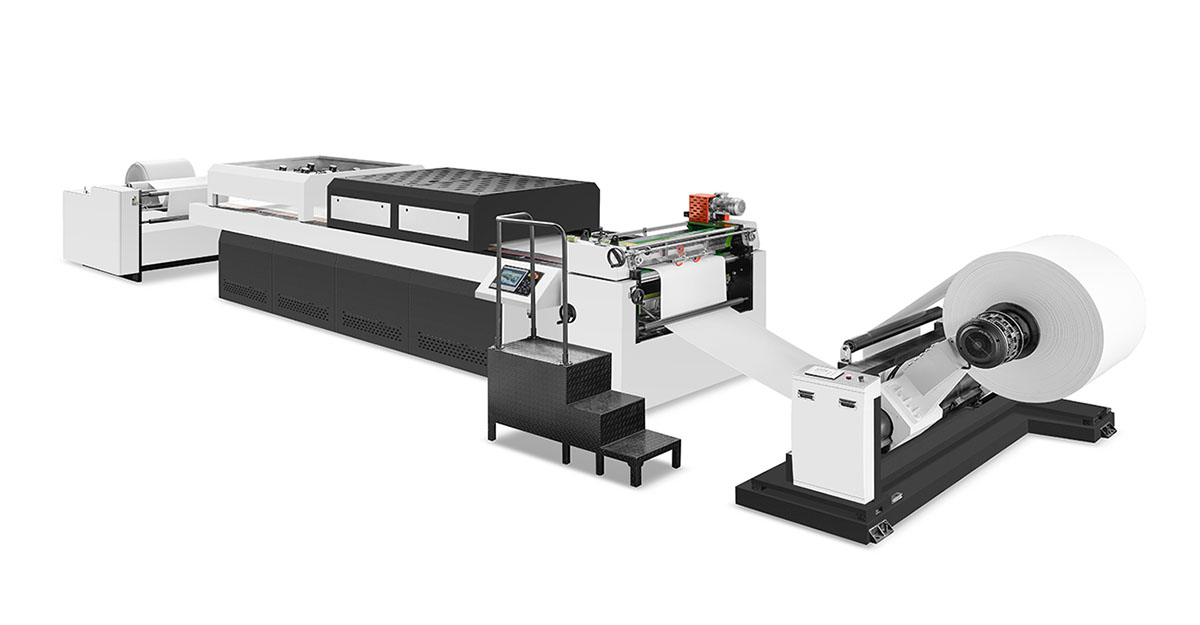

PRODUCT DESCRIPTION

SG-AR series oil varnishing machine which is suitable for the varnishing and polishing process of various paper in roll, machine for water-based oil, UV oil and blister varnish oil coating, after processing the print surface has the damp-proof and water-proof effects. Machine adopts the reversing mechanism to make the oil layer smooth and fine, save varnish oil and meets the high quality requirements.

SPECIFICATION

Model | SG-AR1200 |

Max Paper Width | 1150mm |

Max Rewinding diameter | 1500mm |

Max Unwinding diameter | 1500mm |

Maximum Rewind load capacity | 1200kg |

Maximum Unwind load capacity | 1200kg |

Paper Thickness | 80-600gsm |

Working Speed | 10-100m/min According to printed product thickness, the color and the size of the color block, the running speed of the machine varies. |

Voltage | 380V 50HZ 3P |

Main Motor Power | 1.5KW |

Standby Power | IR:35kw IR+UV:65kw |

Infrared Lamp Power | 1.2kw*18pcs |

Ultraviolet Lamp Power | 8kw*3pcs |

Standard Weight | 6470KGS |

Standard Dimension | 12430mm |

Oil Type | Water Based Oil, UV Oil, Blister Oil, Plastic Oil |

1.It adopts shaftless clamping and hydraulic lifting mode, the tension is controlled manually/automatically by air brake

2.Equipped with CCD vision sensor and rectification controller, photoelectric tracking/tracking or tracking/travel ±75mm, tension is controlled by the system autonomously.

3.Simple and clear panel easy to operate

COATING HOST UNIT

1.Three rollers reversing speed control head to ensure the water-based varnishing effect without streak printing.

2.The metering rollers are individually motor driven to ensure even gluing.

3.Add pedal for workers to step on and use, more convenient to debug the machine, and add railing behind the pedal for more safety.

4.Upgrade the touch screen operation center console, more convenient and accurate operation.

DRYER UNIT

1.Infrared drying with 18pcs Infrared lamp

2.Ultraviolet drying with 3pcs ultraviolet lamp

3.Fan cooling device

4.The intelligent transformer for Ultraviolet lamp (optional), energy saving 30-40%.

REWINDING UNIT

1.It adopts AC vector frequency conversion control and cooperates with the unwinding system. The lifting and lowering of the paper roll is driven by double-cylinder hydraulic pressure. At the same time, it is equipped with a torque adjustment system and an air expansion shaft for winding.