|

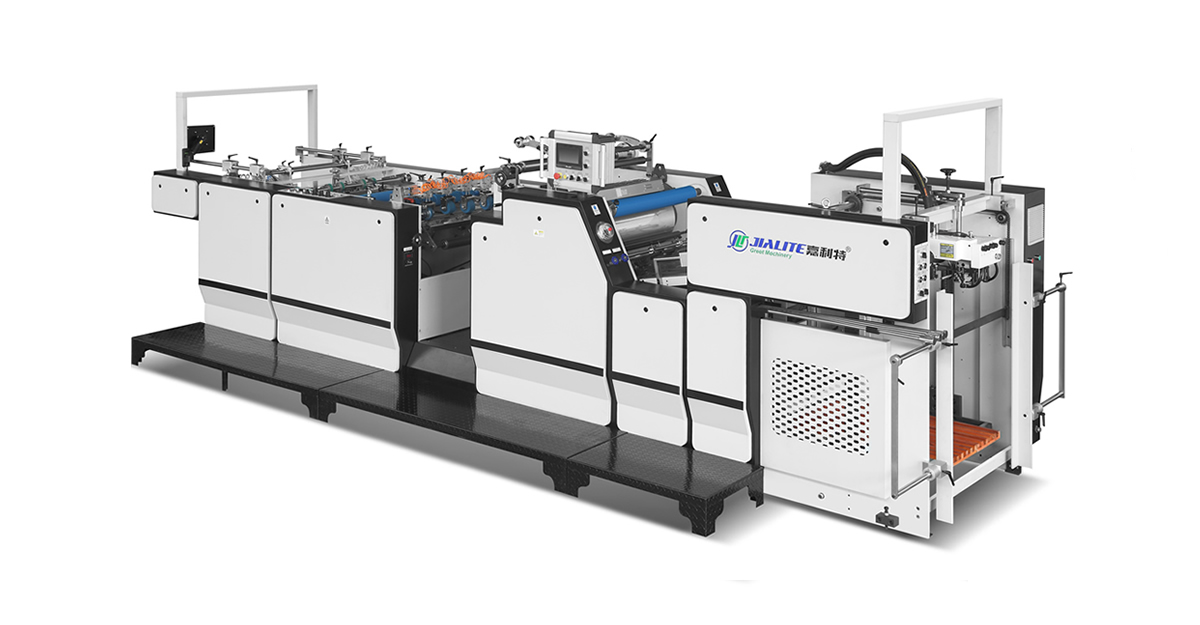

Model |

FY-A800 |

FY-800-1050 |

|

Max. laminating width |

780 mm |

780 mm |

|

Max. sheet |

780 x800mm |

780 x1050mm |

|

Min. sheet |

260 x210mm |

260 x210mm |

|

Paper feeding pile |

1000mm |

1000mm |

|

Heating roller Dia |

380mm |

380mm |

|

Paper thickness |

105 ~ 500 gsm |

105 ~ 500 gsm |

|

Laminating speed |

5~80 m/min |

5~80 m/min |

|

Bopp film thickness |

12 ~ 25μm |

12 ~ 25μm |

|

Max. film roll diameter |

Φ400mm |

Φ400mm |

|

Power required |

25 kw ( 380 V AC3Φ50 / 60 HZ) |

25 kw ( 380 V AC3Φ50 / 60 HZ) |

|

Working power |

18kw / h |

18kw / h |

|

Installed power |

40 KVA |

40 KVA |

|

Dimension(L x W x H) |

6500 x1550 x2080 mm |

7000 x1550 x 2080 mm |

|

Weight machine |

4500kg |

4800kg |

|

Loading size |

20” foot container |

LCL or 40” foot container |